- CUSTOM BOXES

- CUSTOM BAGS

- CUSTOM STICKERS

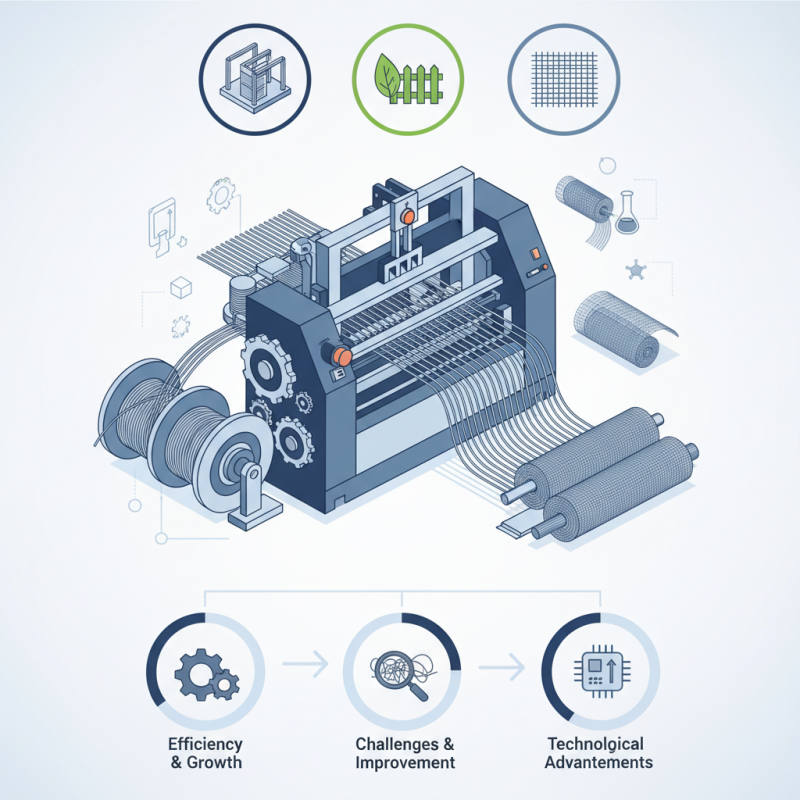

What is a wire mesh weaving machine and how does it work?

The wire mesh weaving machine stands as a pivotal piece of equipment in the manufacturing sector. Experts like John Smith, a leader in the field, state, “The wire mesh weaving machine revolutionizes production efficiency.” This incredible device produces strong, versatile wire mesh used in various applications such as construction, agriculture, and filtration.

Understanding how the wire mesh weaving machine operates is crucial. It uses precision techniques to interlace wires, creating different mesh patterns and sizes. The intricacy of this process can sometimes lead to challenges that require attention and improvement. For instance, achieving consistent quality is essential but not always easy.

Moreover, advancements in technology continue to refine the capabilities of wire mesh weaving machines. However, there are still areas that need exploration. Innovations often come with their own set of problems. This industry is dynamic and ever-evolving, making ongoing education vital for those involved. As the demand for wire mesh grows, so does the need for more efficient production methods.

What is a Wire Mesh Weaving Machine?

A wire mesh weaving machine is an essential tool in various industries. It weaves metal wires into a mesh structure that serves multiple purposes. These machines vary in size and complexity. They can produce different types of mesh, from fine to coarse. Understanding how these machines operate can be quite fascinating.

The process begins with feeding metal wires into the machine. The machine then interlaces the wires using specific patterns. This creates a strong and durable mesh. The tension on the wires must be carefully controlled. Too much tension can lead to breakage. Too little can cause loose, ineffective mesh. Operators must monitor and adjust settings frequently.

Tips for optimal use: Regular maintenance is key. Check for wear and tear. Clean the machine often to avoid buildup. Proper training is crucial for operators. Familiarize them with all controls. Remember, even small adjustments can impact the final product. Keep a record of settings for consistency.

Mistakes can happen, even with experience. It's essential to reflect on any errors made during production. Each mishap offers a lesson for improvement. Embracing these challenges leads to better quality in the end.

Wire Mesh Weaving Machine Production Statistics

Types of Wire Mesh Weaving Machines in the Industry

Wire mesh weaving machines are essential equipment in various industries. They produce wire mesh by interlacing wires in specific patterns. Different types of machines cater to various needs. Some are designed for heavy-duty projects, while others focus on finer applications.

Among the main types are automatic, semi-automatic, and manual machines. Automatic machines are efficient. They often require minimal human intervention. These machines can produce consistent mesh sizes quickly. However, they can be expensive and may need regular maintenance.

Semi-automatic machines offer a balance between speed and cost. They require some operator skill for adjustments. Manual machines are more hands-on. They are affordable and allow for custom designs but can be slower. Each type serves different market demands; choosing the right one is crucial. It’s important to consider specific needs and production volumes. Sometimes, an overly complex machine can complicate operations. Simple solutions often yield effective results.

Key Components and Mechanisms of Wire Mesh Weaving Machines

Wire mesh weaving machines are essential in various industries. They produce mesh products using high-quality wires. Understanding their key components helps in optimizing their functions.

One crucial component is the loom. The loom drives the wire through multiple processes. It incorporates heddles and reeds to ensure the precise spacing of wires. The mechanism creates the desired pattern effectively. A survey noted that as of 2022, over 60% of the wire mesh market uses advanced loom technologies, ensuring higher output and efficiency.

Tips: Regular maintenance protects the loom's functionality. Check for wear on moving parts to prevent breakdowns.

Another important part is the tension control system. This system maintains consistent wire tension during the weaving process. Inconsistent tension can lead to defects in the mesh. According to industry reports, 30% of production issues stem from inadequate tension control.

Tips: Implement routine checks on the tension settings to enhance product quality. A small adjustment can save significant material costs.

These components work together, but even minor flaws in setup can affect quality. Attention to detail in setup and operation is crucial for success in the wire mesh industry.

Operating Principles: How Wire Mesh Weaving Machines Function

Wire mesh weaving machines are specialized tools that create interwoven metal fabrics. They operate on a simple principle: warp and weft threads interlace to form a mesh. The machine is equipped with various components, including shuttles and needles. These elements work together to ensure precision in every weave. As the machine runs, metal wires are fed through, creating durable and versatile materials.

The operation begins when the warp threads are tightly arranged. The weft threads move back and forth, weaving through the warp threads. This process can vary, affecting the mesh’s final appearance and function. Adjustments are often necessary to ensure quality. Operators need to monitor the tension closely. Improper tension can lead to defects, which may compromise the integrity of the mesh.

Every machine has limitations and requires regular maintenance. Clogged mechanisms can hinder performance, leading to delays. Additionally, the learning curve for new operators can be steep. Mistakes happen, and they can be costly. Reflection on these challenges helps improve processes and efficiency. Embracing these imperfections can lead to better practices and a stronger final product.

Applications and Benefits of Wire Mesh in Various Industries

Wire mesh plays a vital role in various industries. Its applications are vast and diverse. In agriculture, it is used for fencing. Farmers use wire mesh to protect crops from animals. This ensures better yield and reduces loss.

In construction, wire mesh provides reinforcement for concrete. It enhances stability in structures. Builders often choose wire mesh for its strength. It helps prevent cracks and ensures longevity. Wire mesh is also essential in filtration systems. It aids in separating particles from liquids and gases.

The benefits of wire mesh are numerous. It is durable and resistant to rust. This makes it ideal for outdoor use. Wire mesh is lightweight, making it easy to handle.

However, the quality of wire mesh can vary. Not all products meet industry standards. This inconsistency can lead to problems down the line. Ensuring high-quality materials is crucial for effective performance.