- CUSTOM BOXES

- CUSTOM BAGS

- CUSTOM STICKERS

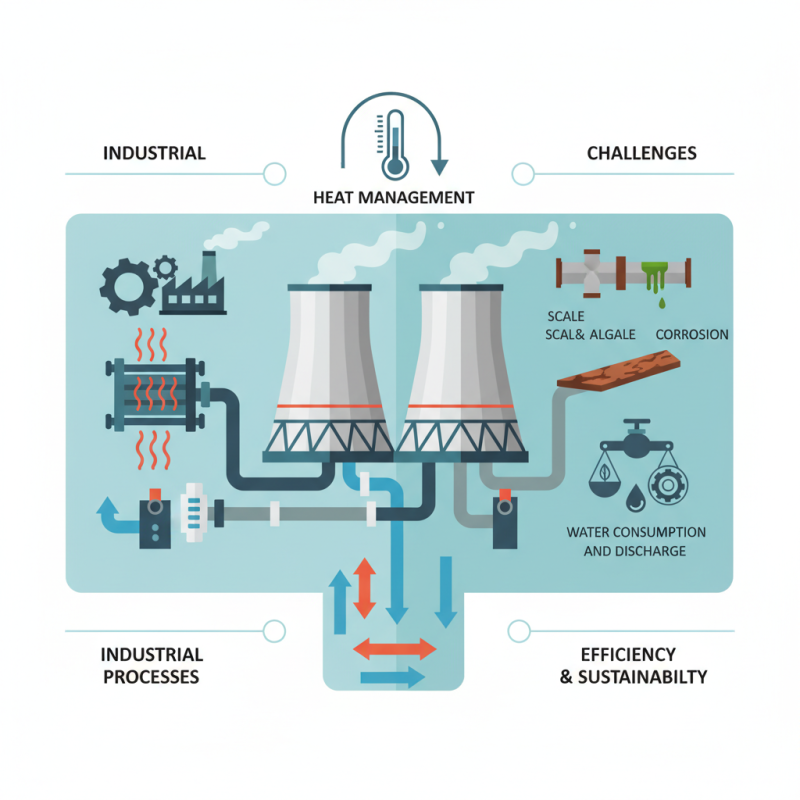

Why Are Cooling Towers Important for Industrial Processes?

cooling towers play a crucial role in various industrial processes. They help manage heat loads in systems, ensuring equipment operates efficiently. According to Dr. Alex Thompson, a leading expert in thermal management, "Cooling towers are the backbone of heat dissipation in industry."

These systems provide a vital service by removing heat from industrial equipment. Without proper cooling, machinery risks overheating. This can lead to breakdowns and costly repairs. cooling towers use water and air to transfer heat, creating a series of challenges. They can be prone to scale, algae, and corrosion, which can hinder their effectiveness.

While cooling towers are essential, they can also contribute to environmental concerns. Water consumption and potential chemical discharges require careful management. Industries must balance efficiency with sustainability. Understanding the importance of cooling towers is key to maintaining operational integrity and respecting environmental needs.

Importance of Cooling Towers in Industrial Processes

Cooling towers play a crucial role in industrial processes. They regulate temperatures, helping systems operate efficiently. These towers remove excess heat from machinery, cooling the circulating water before it returns. According to the U.S. Department of Energy, up to 30% of energy use in manufacturing processes can be attributed to cooling. Efficient cooling systems can reduce energy costs significantly.

In industries like power generation and manufacturing, cooling towers are vital. They maintain optimal temperatures, preventing equipment from overheating. A report from the International Energy Agency states that improving cooling efficiency could save billions in energy costs annually. However, not all cooling towers operate effectively. Some suffer from poor maintenance or outdated designs, leading to inefficiencies.

Water treatment is another aspect to consider. Improperly managed cooling towers can lead to scale buildup and corrosion. This can compromise their effectiveness. A recent study showed that approximately 30% of cooling systems experience problems due to such issues. Regular maintenance and monitoring are essential. Addressing these concerns can enhance both performance and longevity.

Importance of Cooling Towers in Industrial Processes

Basic Principles of Cooling Tower Operation

Cooling towers play a crucial role in industrial processes. They help regulate temperatures in plants and factories. Understanding their operation is essential for efficient use. The basic principle involves transferring heat from water to the atmosphere. Hot water enters the tower and is exposed to air. As water droplets fall, they evaporate, taking heat away.

This process relies on specific factors. The humidity level and air temperature affect evaporation rates. In high humidity, efficiency drops. Many operators overlook this issue, leading to suboptimal performance. Regular maintenance is necessary to ensure airflow is not obstructed. A clogged fan can ruin efficiency and raise costs.

Design and location also matter. Towers require adequate space for airflow. Placing them near heat sources is ideal. However, environmental impact should not be ignored. Noise and water use may become problematic. Proper assessment is vital to align with sustainability goals. Each setup is unique, requiring tailored solutions. Engaging experts can help navigate these complexities.

Common Applications of Cooling Towers in Industries

Cooling towers play a crucial role in various industrial processes. Industries rely on these structures to manage heat generated during operations. They provide an effective way to dissipate excess heat, ensuring equipment runs efficiently. The American Society of Mechanical Engineers reports that poorly managed thermal processes can reduce efficiency by up to 15%.

In manufacturing, cooling towers are commonly used in power plants and chemical facilities. For instance, power plants often consume vast amounts of water for cooling. This system allows them to recycle water, minimizing wastage. In fact, a single cooling tower can reduce water consumption by approximately 40%. However, issues can arise, such as Legionella bacteria growth when maintenance is overlooked.

Another application is in HVAC systems, where cooling towers enhance air conditioning efficiency. Facilities can save energy costs by optimizing heat exchange. Some surveys suggest that optimally managed cooling towers can cut energy use by 20%. Still, companies often struggle with regular maintenance schedules. Proper cleaning and inspections are necessary to avoid inefficiencies.

Why Are Cooling Towers Important for Industrial Processes? - Common Applications of Cooling Towers in Industries

| Industry | Application | Cooling Capacity (kW) | Water Source |

|---|---|---|---|

| Power Generation | Nuclear and Thermal Plants | 15,000 - 100,000 | River or Lake Water |

| Manufacturing | Chemical Processing | 5,000 - 25,000 | Municipal Water Supply |

| Food and Beverage | Cooling in Bottling Plants | 1,000 - 10,000 | Well or Groundwater |

| HVAC | Commercial Air Conditioning | 500 - 5,000 | City Water Supply |

| Data Centers | Cooling of IT Equipment | 10,000 - 50,000 | Recycled Water |

Benefits of Cooling Towers for Energy Efficiency

Cooling towers play a crucial role in industrial processes. They help manage heat by dissipating excess warmth. This action improves the overall efficiency of machinery and processes. By maintaining optimal temperatures, cooling towers contribute significantly to energy conservation.

Energy efficiency is a key benefit of cooling towers. They use water to absorb heat, which can save on electricity costs. When equipment runs cooler, it often performs better. Over time, this can lead to substantial savings for businesses.

Tip: Regular maintenance is essential. Clean the cooling tower to avoid buildup, which can impede efficiency.

Another advantage is the reduction of water consumption. Advanced designs recycle water, minimizing waste. This approach not only benefits the environment but also lowers operating costs. Consider investing in modern cooling solutions for long-term benefits.

Tip: Monitor water levels closely. Ensure that you adjust regularly to maintain performance and prevent overuse.

Maintenance and Management of Cooling Tower Systems

Cooling towers play a crucial role in various industrial processes. They help manage heat generated by equipment. Effective maintenance is essential for their performance. Regular checks can prevent major issues. However, many facilities overlook this critical task.

Proper water treatment is also vital. Scaling and corrosion can jeopardize efficiency. Many plants neglect those aspects, leading to costly repairs. It's important to address these problems regularly. A consistent maintenance routine may seem burdensome. Yet, it ultimately saves time and resources.

Management of cooling tower systems requires attention to detail. Operators should monitor water levels and temperatures daily. Unexpected fluctuations can signal underlying problems. Training staff to respond promptly is key. Mistakes can happen, but learning from them improves processes.