- CUSTOM BOXES

- CUSTOM BAGS

- CUSTOM STICKERS

10 Essential Tips for Effective Box Printing Success?

Box printing is a crucial aspect of product packaging. According to industry expert James Collins, "Quality box printing can change the perception of a brand." This underscores the importance of effective box printing processes.

Every detail matters. From color choices to material selection, each decision impacts the final product. It’s easy to overlook minor aspects, but these can lead to pitfalls. Many businesses struggle with alignment issues or color inconsistencies. These mistakes not only affect quality but also brand image.

Understanding customer needs is vital. Communicating with clients can prevent unnecessary reprints. Regular feedback can guide improvements in designs or materials. Effective box printing is not just about aesthetics; it’s about functionality. Balancing both can lead to greater success in the market.

Understanding the Importance of Quality Box Printing

Quality box printing is crucial for businesses that want to make a positive impression. High-quality printing attracts customers and communicates professionalism. Details like colors and textures matter. Perfect packaging grabs attention and builds brand identity. Companies often overlook the importance of this aspect. When boxes look cheap or faded, they can detract from the product's value.

Visibility in a crowded market is important. Unique designs can set a product apart. However, it’s not just about aesthetics. The durability of materials also plays a vital role. Boxes need to protect their contents. If a box fails during transport, the product may be damaged. This can lead to customer dissatisfaction. Investing in materials that offer both strength and visual appeal can make a significant difference.

Moreover, businesses sometimes underestimate printing costs. It can be tempting to cut corners, but this often backfires. Poor quality can harm a brand's reputation. Reflection on past printing choices is necessary. Evaluating what worked and what didn’t can lead to better outcomes. Quality should always be at the forefront of any packaging decision.

Choosing the Right Materials for Box Printing

Choosing the right materials for box printing is crucial to achieving the desired results. The type of paper can significantly impact the box's strength and appearance. For instance, cardboard is sturdy and ideal for shipping. Options like eco-friendly paper are great for sustainability. However, not all materials work well for every design.

When selecting materials, consider the weight and finish. Matte print finishes can give a sophisticated touch, while glossy options enhance colors. It’s vital to test samples to see how designs translate on materials. Inconsistent results can happen if the printing method doesn’t match the material. A misalignment can lead to a lack of vibrancy in colors.

Tip: Always check compatibility between your design and selected material. Remember, lighter materials might not hold intricate designs well. Take your time during the selection process. It's easy to overlook this. Choose wisely to avoid costly mistakes down the line.

Designing an Eye-Catching and Functional Box Layout

Creating an eye-catching box layout requires careful planning and creativity. Begin by understanding your target audience's preferences. Studies show that 70% of consumers judge a product by its packaging. If your design is uninspired, potential customers may overlook your product. Remember, the box is often the first impression.

Choosing colors wisely is crucial. Research indicates that 90% of snap judgments about products are based on color alone. A vibrant, well-thought-out palette can evoke emotions and attract interest. Ensure the typography complements the design, as readability is key. Many designs fail because they prioritize aesthetics over functionality.

Consider including practical elements, like easy opening features. Frustrated customers often abandon products if packaging is difficult to navigate. Reflect on your design choices. Are they merely eye-catching, or do they enhance the user experience? An effective layout should balance visual appeal and usability, guiding the consumer seamlessly from unboxing to engagement.

Box Printing Success Metrics

The following chart illustrates the effectiveness of different design elements in box printing, based on a survey of industry professionals. It highlights key aspects that contribute to creating eye-catching and functional box designs.

Selecting the Appropriate Printing Techniques for Your Needs

Selecting the appropriate printing techniques for box printing is crucial. The technique should match your design and material needs. Digital printing works well for vibrant designs and smaller runs. However, it may not be the best choice for large volumes or specific textures. Flexography is a popular option for mass production but often limits color depth.

Consider the type of box you want. Corrugated boxes may benefit from rotary screen printing, which offers durability. Also, think about the finish. Matte or glossy? Each provides a different look and feel. Sometimes, a simple design can lead to better production efficiency. Cost is another factor. Cheap options may lead to lower quality results. Reassess your needs regularly to avoid mistakes that could cost time and money.

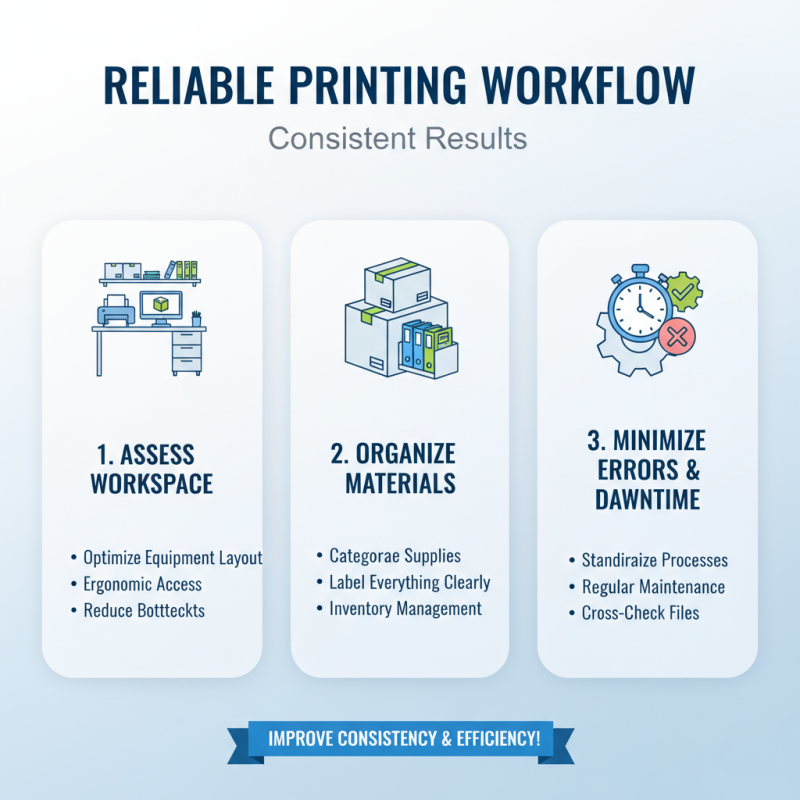

Establishing a Reliable Printing Workflow for Consistent Results

Establishing a reliable printing workflow is crucial for consistent box printing results. Start by assessing your workspace. Ensure that your equipment is arranged for efficient access. Keep materials organized. This can significantly reduce errors and downtime.

Next, focus on the calibration of your printing machines. Regular check-ups are necessary but often overlooked. A minor misalignment can lead to major flaws. Document each setting you adjust. This habit creates a reference for future adjustments.

Train your team thoroughly. While skills can improve over time, the initial learning curve can be challenging. Encourage feedback on the workflow. This will help identify bottlenecks. Reflect on what needs change. Be open to trial and error; it’s a part of the process.

Related Posts

-

Exploring the Future of Box Printing: Innovative Techniques and Eco-Friendly Materials

-

How to Start Box Printing for Your Small Business?

-

Why Choose Personalized Packaging Bags for Your Business Needs?

-

The Impact of Personalized Packaging Boxes on Consumer Behavior: Insights from Recent Market Research

-

Why Good Tea Packaging Matters for Freshness and Quality Preservation

-

The Ultimate Guide to Eco Friendly Cookie Packaging Supplies for Sustainable Baking