- CUSTOM BOXES

- CUSTOM BAGS

- CUSTOM STICKERS

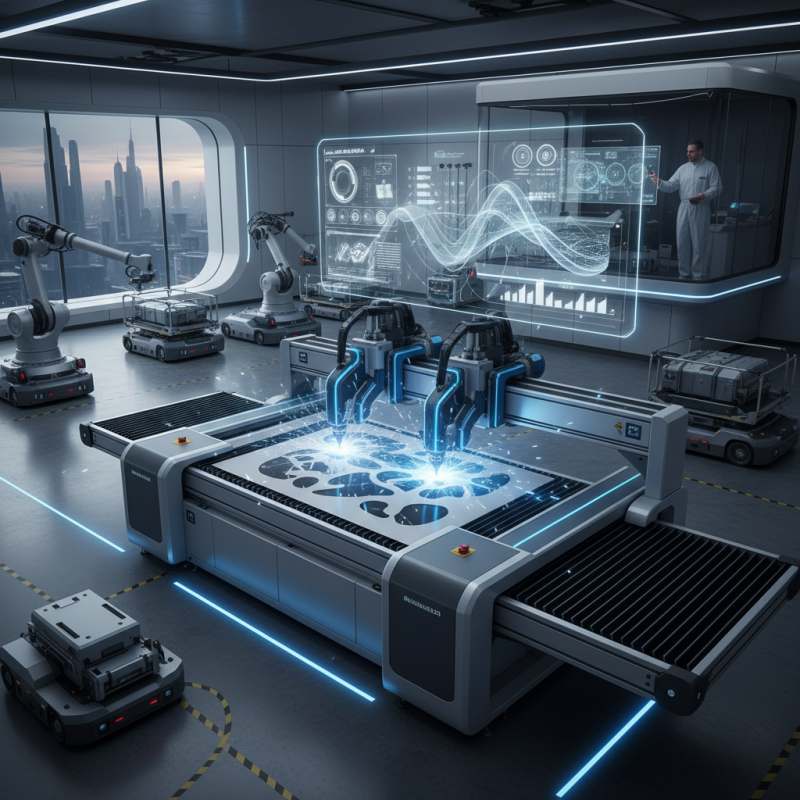

2026 Top Laser Cutting Machine Trends and Innovations?

In the rapidly evolving world of manufacturing, the laser cutting machine stands at the forefront of innovation. Industry expert Dr. Emily Harmon once stated, "Laser cutting technology is reshaping how we think about precision and efficiency in production." This quote encapsulates the revolutionary potential that laser cutting machines embody.

As we look toward 2026, several trends emerge. Manufacturers increasingly focus on automation and artificial intelligence to enhance the capabilities of laser cutting machines. New materials are also becoming more common, allowing for greater creativity in design. These advancements not only streamline processes but also pose questions about quality control and worker adaptation.

Despite the exciting progress, challenges remain. Integration of new technologies into existing systems often requires time and significant investment. Additionally, there is a need for continuous training to keep workers updated. The laser cutting machine industry must navigate these complexities while embracing change. The future is bright, but it demands careful consideration and reflection on how best to proceed.

Emerging Technologies in Laser Cutting Machines for 2026

As we approach 2026, the landscape of laser cutting machines is evolving rapidly. One noteworthy trend is the integration of artificial intelligence. AI algorithms can enhance precision and efficiency in laser cutting. These advancements help minimize material waste and reduce production costs. Imagine a machine that learns from previous cuts, adapting to different materials seamlessly.

Another innovation is the move towards more eco-friendly technologies. Laser cutting machines are beginning to incorporate energy-efficient systems. This not only reduces carbon footprints but also lowers operational costs. Users will likely reflect on their environmental impact while enjoying the benefits of advanced features.

However, these emerging solutions bring challenges too. The complexity of new systems can overwhelm operators. Training might not keep pace with technological advances, leading to potential mishaps in production. Striking a balance between innovation and usability will be crucial as the industry moves forward. Understanding these dynamics can shape a more effective approach to implementing modern laser cutting technologies.

Advancements in Laser Cutting Precision and Speed

The advancements in laser cutting technology are remarkable. Precision is reaching new heights. Machines can now cut through materials with intricate details. This is critical in industries like aerospace and automotive. The capability to achieve such fine details reduces the need for secondary processes. It saves both time and resources.

Speed continues to improve alongside precision. New systems utilize advanced algorithms. These algorithms analyze data in real-time. They optimize cutting paths and reduce idle times. The results are faster production rates without sacrificing quality. However, this speed can create challenges. Companies must ensure equipment maintenance is a priority. Without it, speed gains may lead to errors.

As technology evolves, there’s a risk of becoming too reliant on automation. Human oversight is essential, especially for complex projects. Workers still need to assess machine outputs. A balance is necessary. While the innovations are exciting, it is crucial to avoid blind faith in them. Continuous evaluation and adjustment can foster better outcomes.

Sustainability Trends in Laser Cutting Machine Manufacturing

Sustainability is reshaping laser cutting machine manufacturing. The focus on reducing carbon footprints is stronger than ever. According to a recent report, 70% of manufacturers aim to adopt eco-friendly practices by 2026. Energy-efficient systems are becoming crucial. These systems reduce power consumption significantly.

Laser cutting technology itself is evolving. Efficient materials with minimal waste are now prioritized. The industry sees a trend towards recyclable materials. Data shows that about 62% of manufacturers utilize recyclable options in their machinery. This shift reflects a growing awareness of environmental issues. However, challenges remain. Many companies struggle with the initial costs of sustainable technology. Short-term profits often overshadow long-term benefits. Change requires investment and commitment, which some manufacturers hesitate to make.

While many advancements are promising, the pace of adoption is uneven. Some businesses still cling to outdated practices, resisting innovation. There is a pressing need for a cultural shift within the industry. Greater collaboration between companies could accelerate sustainable practices. Industry leaders must address these gaps to create a truly green future for laser cutting technology.

2026 Top Laser Cutting Machine Trends and Innovations - Sustainability Trends in Laser Cutting Machine Manufacturing

| Trend/Innovation | Description | Environmental Impact | Market Adoption Rate (%) |

|---|---|---|---|

| Fiber Laser Technology | Higher efficiency and precision in cutting. | Reduced energy consumption compared to CO2 lasers. | 45% |

| Automation and AI Integration | Smart machines that optimize cutting paths. | Minimized waste through efficient operations. | 30% |

| Sustainable Materials | Focus on recyclable and biodegradable materials. | Lower carbon footprint in end products. | 35% |

| Energy-Efficient Designs | Optimize machine design for less power use. | Reduced operational costs and emissions. | 40% |

| Remote Monitoring and Maintenance | Utilizing IoT for real-time machine health. | Extended machine life and lower waste. | 25% |

Integration of Artificial Intelligence in Laser Cutting Processes

The integration of artificial intelligence in laser cutting processes is transforming the manufacturing landscape. AI enhances precision and efficiency, making operations smoother. Factories using AI can analyze data in real-time, adjusting cut patterns and speeds. This leads to reduced waste and improved product quality. However, reliance on AI can also spark concerns about job displacement.

Tips: Regularly training staff on AI tools can help bridge the gap. A collaborative approach between humans and AI may boost productivity. Encourage continuous learning to stay ahead.

Artificial intelligence also introduces challenges. Systems need constant updates and maintenance to function effectively. This can lead to unexpected downtime, affecting production schedules. Without proper oversight, AI can misinterpret data, leading to costly mistakes. Balancing technology and human touch is vital.

Tips: Implement a feedback loop to monitor AI decisions. Regular audits can catch errors before they escalate. Encourage team members to voice concerns about the processes.

Future Applications of Laser Cutting Across Various Industries

Laser cutting technology is rapidly evolving, reshaping industries from manufacturing to healthcare. In the automotive sector, for example, laser cutting helps in improving precision in part manufacturing. The precision can increase production efficiency by up to 30%, according to recent reports. This advancement is crucial as the demand for custom components grows.

In the healthcare field, lasers are being used for cutting medical instruments and implants. The accuracy of laser cutting minimizes risk during surgeries. Reports indicate that the use of laser technology in medical applications has increased by over 25% in the last five years. Despite these benefits, challenges remain. The high initial costs of equipment can deter small businesses from adopting this technology.

Furthermore, environmental concerns are also prominent. The process often involves significant energy consumption. As sustainability becomes a vital issue, the industry must find ways to mitigate environmental impacts while harnessing laser cutting's advantages. The continuous evolution of this technology calls for both innovation and critical reflection on its broader implications.